About Us

Manufacturing Facilities

43,500 sq. ft. integrated manufacturing facility

Advanced CNC machining and assembly lines

In-house testing for performance and quality assurance

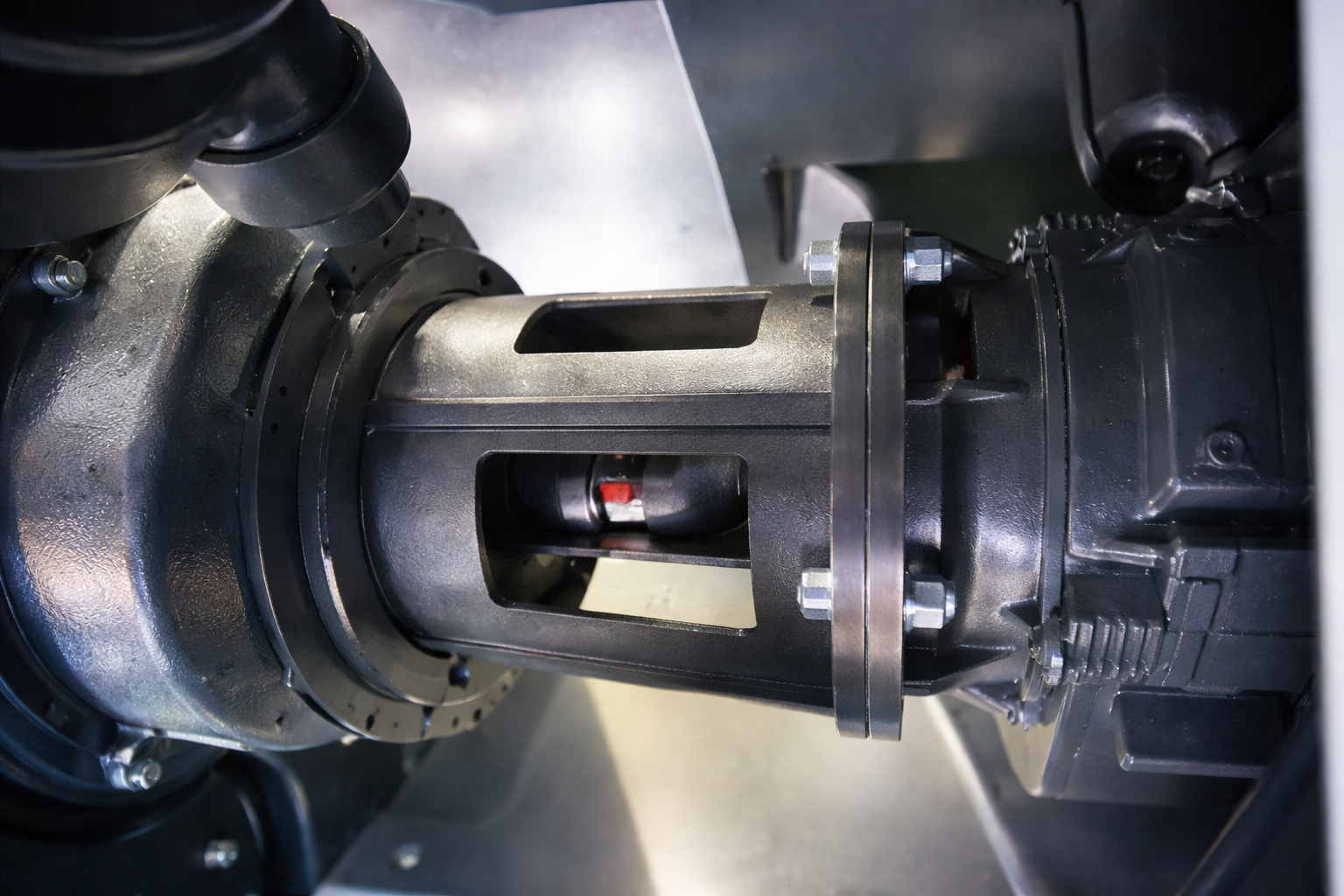

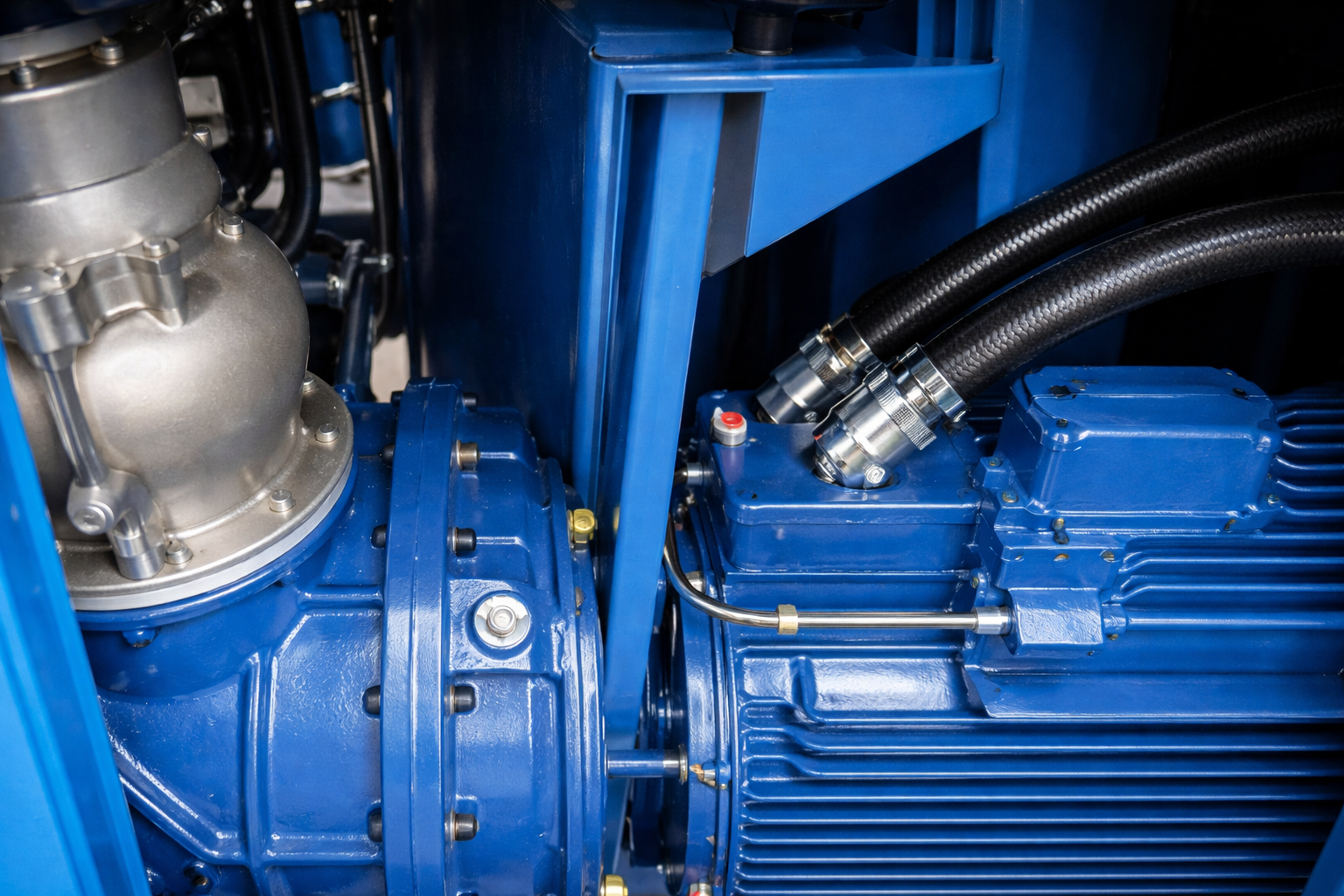

Heavy Duty Coupling with Zero Transmission Loss

Heavy-duty direct-drive coupling system connecting the motor and airend, designed to ensure zero transmission loss. The coupling is robust, precision-aligned, and suitable for continuous industrial operation.

Premium High Performance Synthetic Compressor Oil

High-performance synthetic oil increases bearing life above 40,000 running hours Energy savings achieved approximately 2.5% to 3%

Superior Air Filter

Two-stage dust removal air filter highly efficient and filtering system with efficiency of up to 99.9% even in heavy-duty environments.

Extends the service life of the compressor parts and components, ensures high air quality.

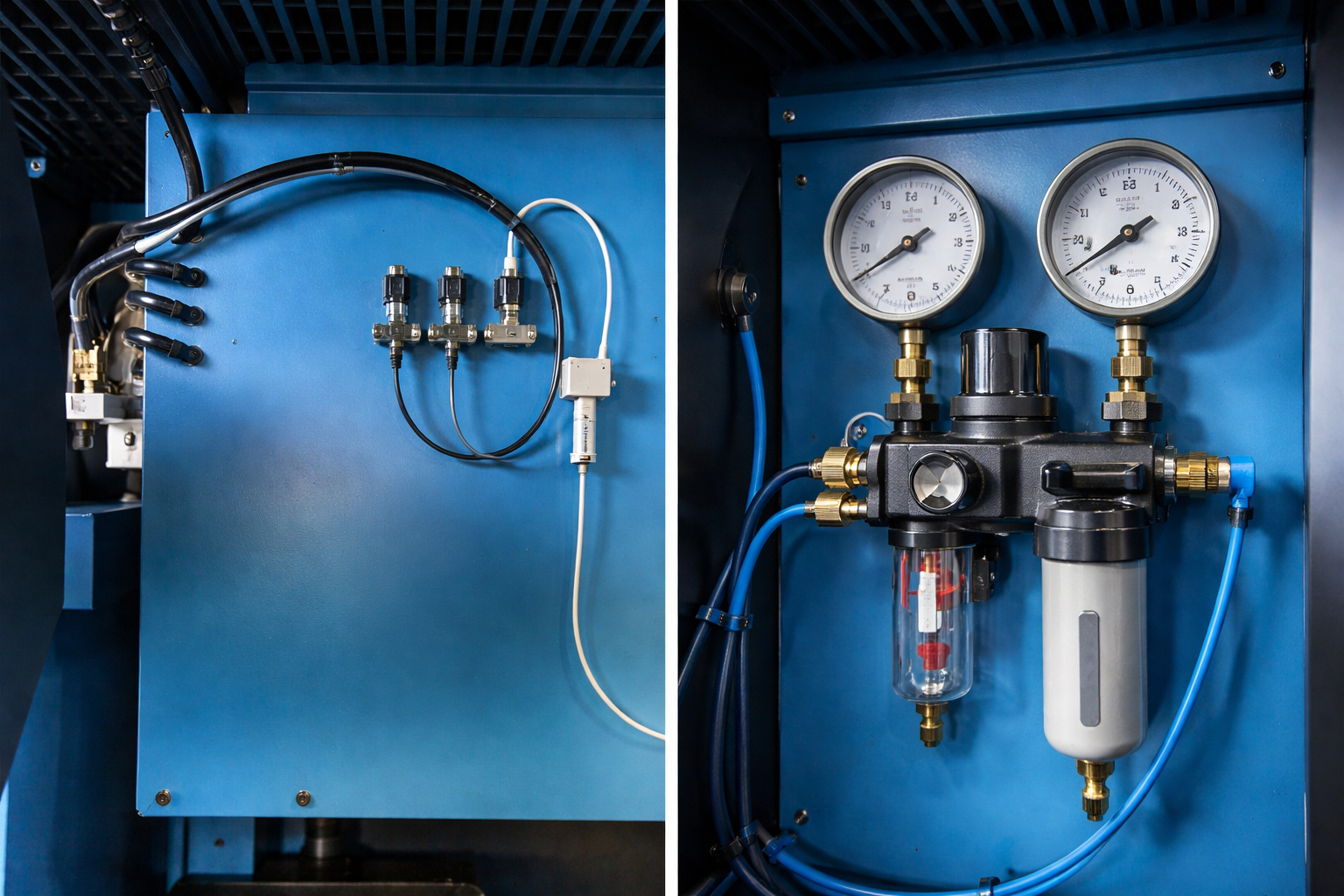

Protection Against Any Abnormal Pressure and Temperature

Highly sensitive pressure and temperature transducers are provided to protect the machine in case any abnormality is observed.

Latest German Brand Airend First Row With True Direct Driven

True direct drive airend, very robust and reliable

5:6 rotor profile

No gearbox

Highly Efficient Air Inlet Valve

Large suction area

Valve seat made of fluoro rubber

for high reliability during operation and providing longer life to the equipment.

Heavy Duty Canopy for Sound & Vibration Protection

Heavy-duty canopy resists sound and vibration levels.

Ensures quieter operation and enhanced machine protection

Two-Stage Airend

Low speed and low noise

Airend life: 50,000 to 60,000 running hours

Highly Energy Efficient

Steel Oil & Air Pipes

High temperature resistant (400 C~752 F) and

low temperature resistant (-270 C ~ -518 F),

high pressure resistant.

Ultra-long life (20 years), completely leak free and maintenance free.

Efficient Separation System

Three-stage air-oil separation (centrifuge, gravity, filter)

Oil content: less than 3 ppm by weight

Efficient Cooling System

High-quality aluminium fins and copper coil material

Excellent thermal conductivity ensures perfect cooling efficiency

Axial Fan

High-efficiency axial fan

Fan starts/stops based on temperature reducing energy.

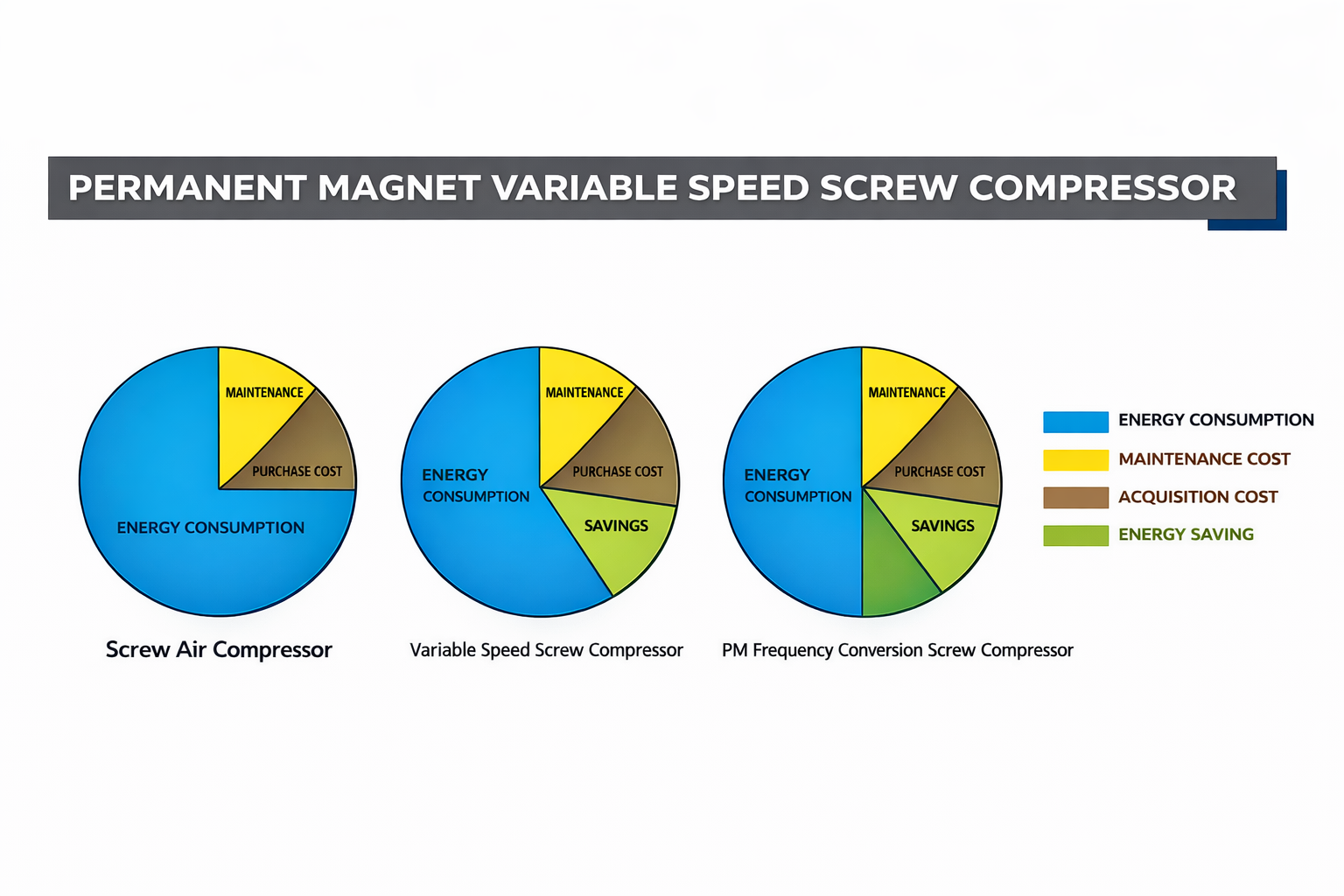

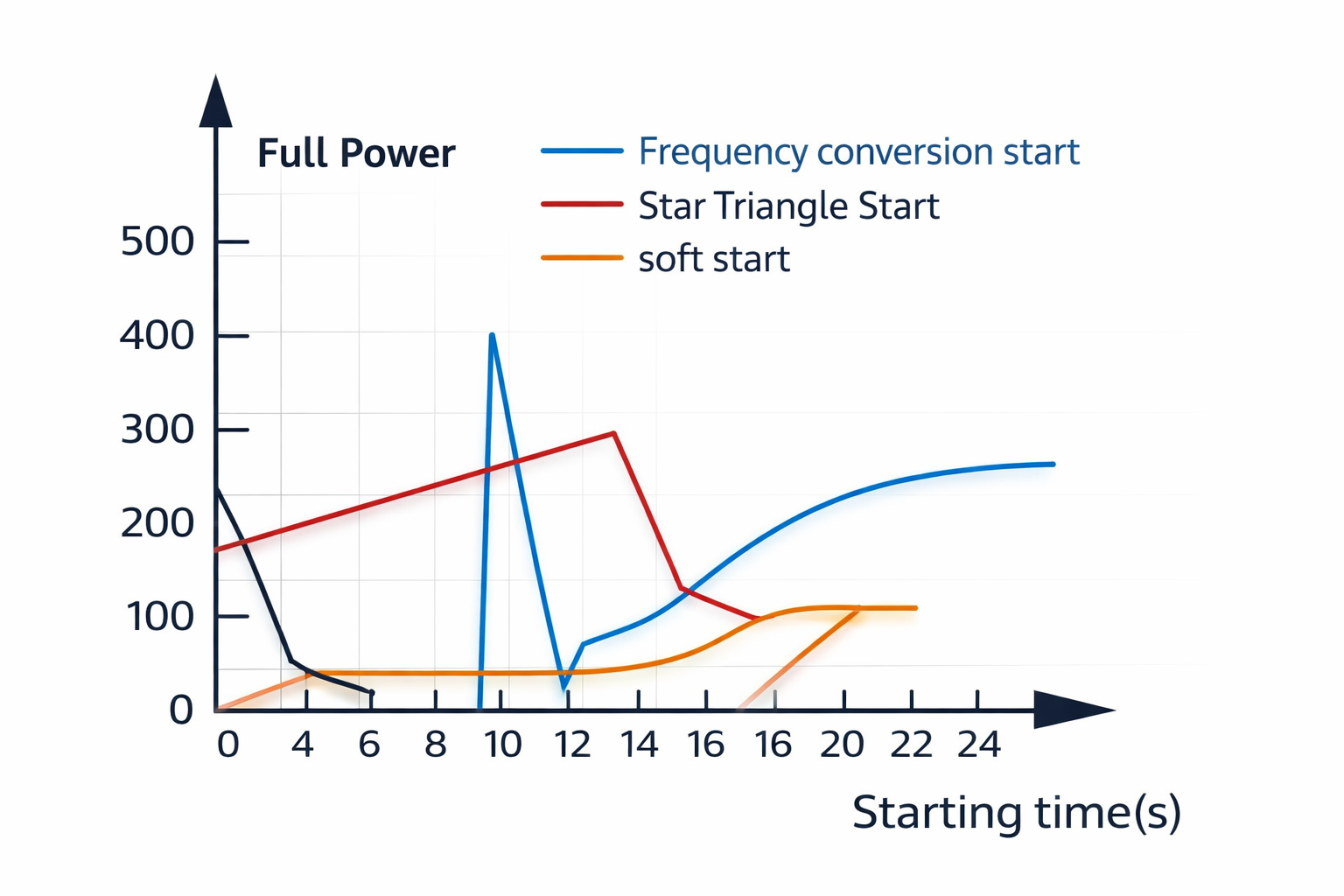

Advantages Of Variable Over Fixed Speed Screw Compressors

Graphical Presentations Of Energy Saving With Paremanent Fixed & Variable speed screw compressors

More reliable

- The frequency conversion machine starts smoothly and can avoid the peak current which might burden your whole power supply.

- Avoiding the negative factors from constant high speed running.

- Lowing the possibility of system leak by setting the surpass pressure under 2 bar.

Energy saving

- With the variable speed system, the output pressure of the compressor can perfectly match with the demand of the system, which avoid no-load energy consumption.

- Under the constant air demand, the frequency conversion system can start without peak current, which avoids the overload and allows the compressor to stop frequently.

- With 2 bar output pressure control, the system can save 14% on energy consumption.

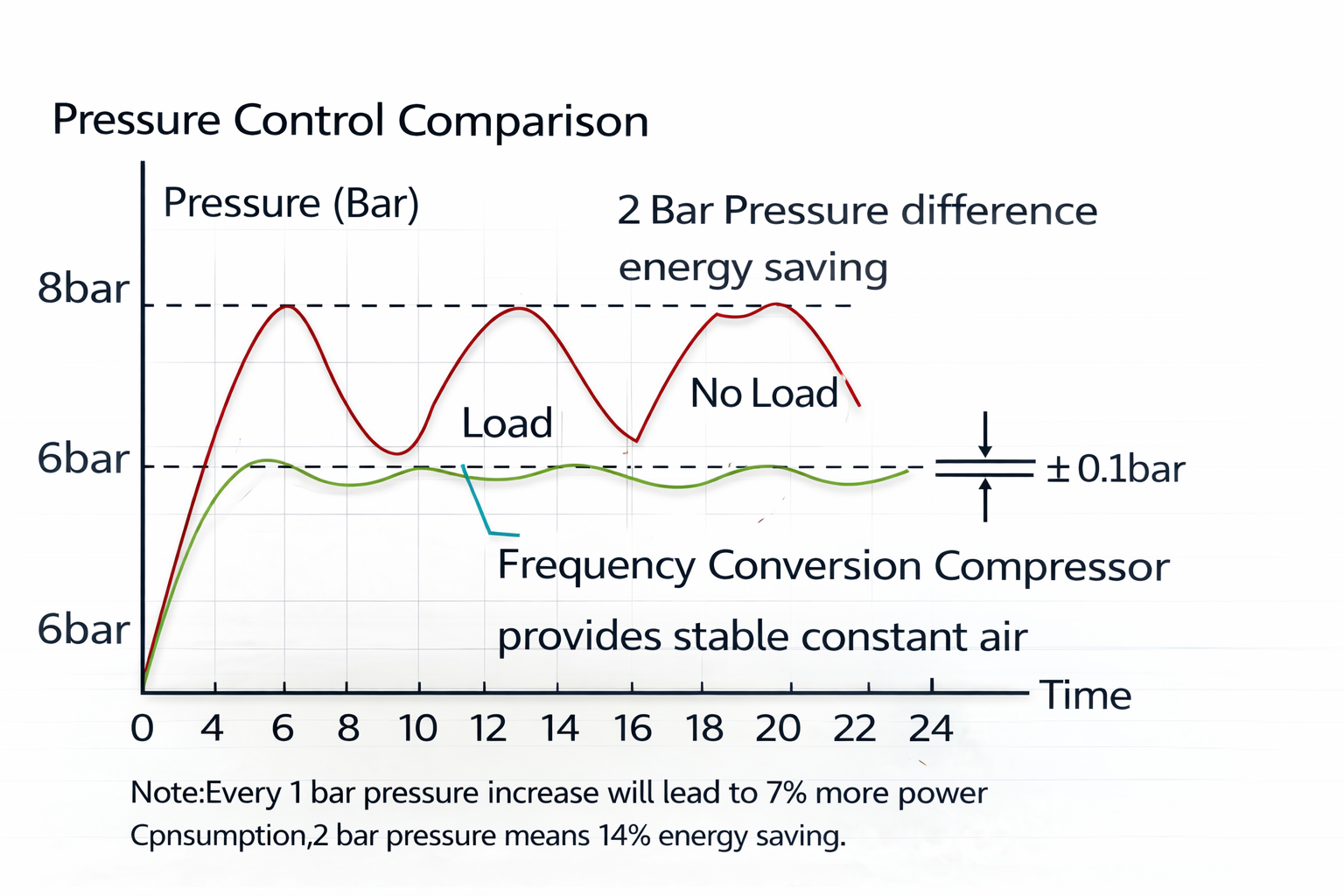

Stable Air

- The displacement pressure can be set between 3–14 bar without gearbox or belt.

- A pre-set stable constant pressure will be output in a range of ±0.1 bar.

- When the system has a high demand of air, the machine will run faster and keep providing stable air.

- When the system has a low demand of air, the machine will run slower and keep providing stable air.

Graphical Presentations Of Energy Saving With Permanent Magnet speed screw compressors